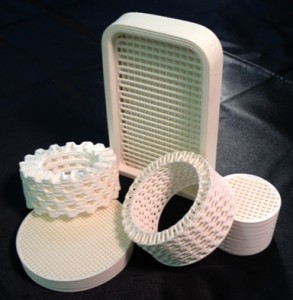

3D printed ceramic filters for molten metal

LATTICE Filters™ exhibit high strengths, reproducible tortuous pathways, thermal shock resistance, and introduce no debris into the filtrate. Each Filter that we produce is high fired to fully sinter the ceramic body. They will not “dust” or “snow” to release impurities into your melt. Ceramic foam filters have variable pore sizes and internal surface areas. These properties are dependent on many environmental variables that are not held consistent during manufacturing. Each of our filters can be customized to increase filtration or flow rates. We can control the internal surface area and the pore size with each casting. These 3D printed ceramic filters’ filtration levels and flow rates are easy to reproduce. Consistently high internal surface areas, no line-of-site pathways, and consistent flow improve their performance. Lattice Filters™ are ENGINEERED structures.

Our filters have shown excellent results in multiple aluminum and copper alloys.

Lattice Filters™ can be produced out of many different ceramic materials. Popular choices include mullite, alumina, zirconia-toughened mullite, and stabilized zirconia. Talk to one of our sales engineers for a quote today!